Condenser

It may not be that familiar. It is mainly used to convert the outlet steam from turbine (for power generation, etc.) into the form of liquid water. Generally, condensers are put in a vacuum state (below atmospheric pressure) in order to lower saturated temperature, and water is used for cooling. Photos below show a condenser for the private power generation facility by one of our customers from a paper manufacturing company.

It is in production.

Golden colored disc is called “tube plate”.

We consider heat exchanger’s tube plate as equipment’s face.

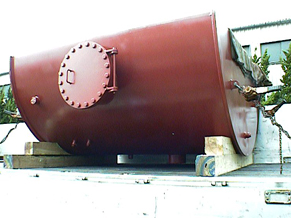

Once water chamber cover is attached, it is ready to ship.

It is lifted by 2 cranes and loaded on a trailer, and then transported.

Hot well, in which water condensed from steam is collected, is usually sent separately.

After a shell body is installed, it is welded to the bottom of the body.

Above is the limitation in size for land transportation (by trailer).

If the size is larger than above, we can either (i) ship parts and assemble on site, or (ii) transport by sea.

Our factory is located along the coast and it is only 200 meters away from the wharf, so we can transport by sea without size limitations as long as it can be manufactured by our factory.

At the same time, we also need to consider the location at our customer side, whether it is located near the sea or how far it is from the arrival port to the site.