Side Entry Condenser

Condensers are usually installed underneath the turbine so it requires a facility (building) with two or more floors.

On the other hand, side entry condensers can be installed on the same floor with turbine, so it can be beneficial to reducing facility cost and shortening construction period.

Although normal condensers are connected to the turbine through an expansion joint in order to absorb thermal expansion of the equipment,

side entry condensers cannot use such expansion joint since it is operated in a vacuum state,

so it should be connected in a different way from normal condensers.

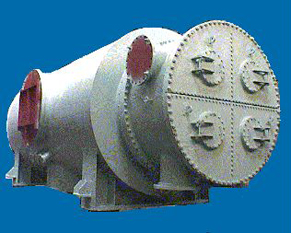

This photo shows a condenser for steam turbine with 1560m2.

Steam flows in from the left side.

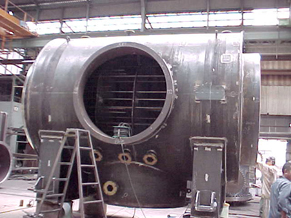

Same as the photo above, steam flows in from the left side.

This condenser has an unusual shape.

You can see 2 belt-like things on the body and these are the protection for lifting.

Side entry condenser is in production.

A big hole in the middle is steam inlet.